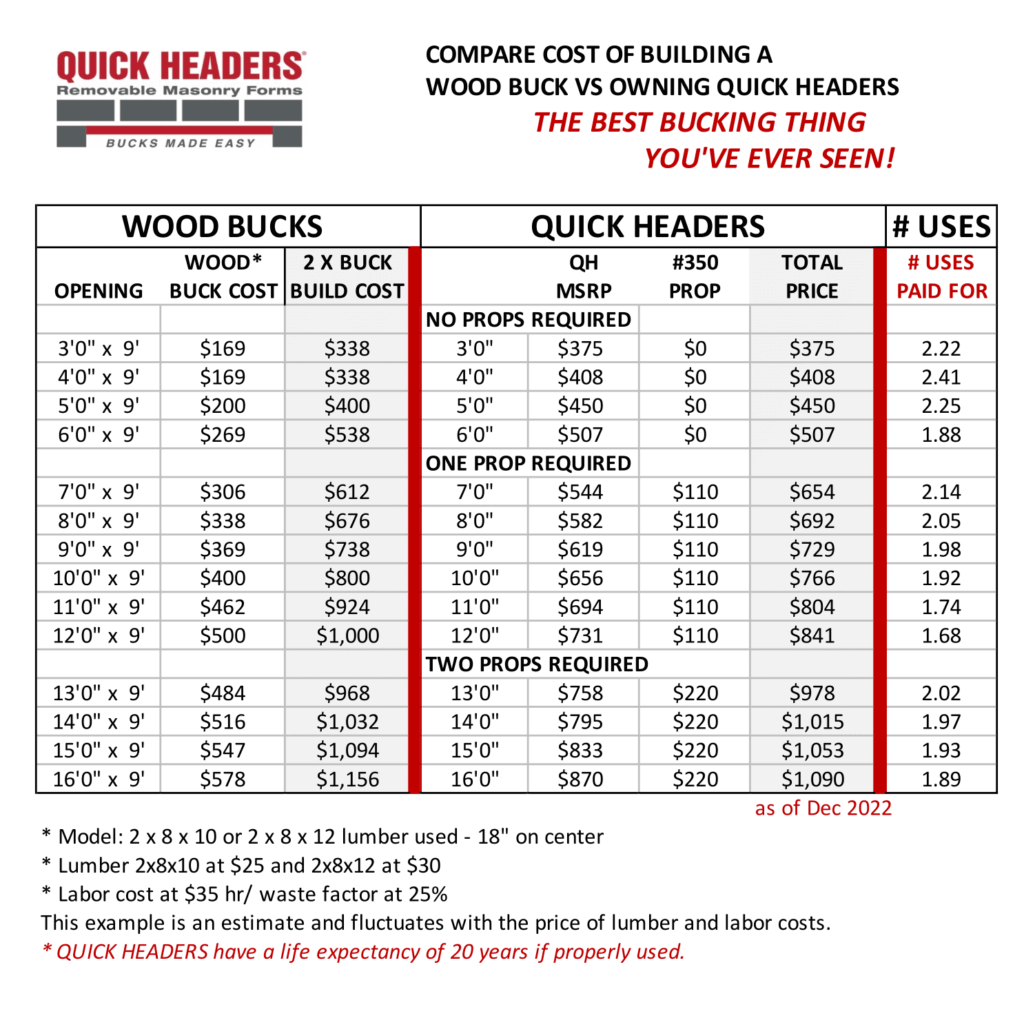

When truly comparing the material, labor and waste costs associated with building wood bucks, Quick Headers substantially out-performs building wood bucks every time. Comparing all size openings, the following chart demonstrates that the one-time cost paid to purchase a Quick Header with a life expectancy of 20+ years, is paid for after building only two wood bucks of the same size that have only a one time use. Owning Quick Headers vs Building Wood Bucks? There is no comparison… Quick Headers are changing the industry standing in masonry shoring with an efficient and effective system that ends costly work stoppages, improves labor efficiencies, eliminates wood waste, is focused on safety, and all with a high return on your investment.